The Bolong die-casting workshop has a total of six 180-1250 tons of Yizhi, including three sets of fully automatic die-casting islands. It is equipped with advanced auxiliary equipment such as concentrated melting furnace, dumping furnace, electric holding furnace, vacuum machine and high-pressure point cooler, which can ensure the stable production of the company's die-casting products and meet the production needs of high-end customers with difficult products.

Die casting workshop |

|

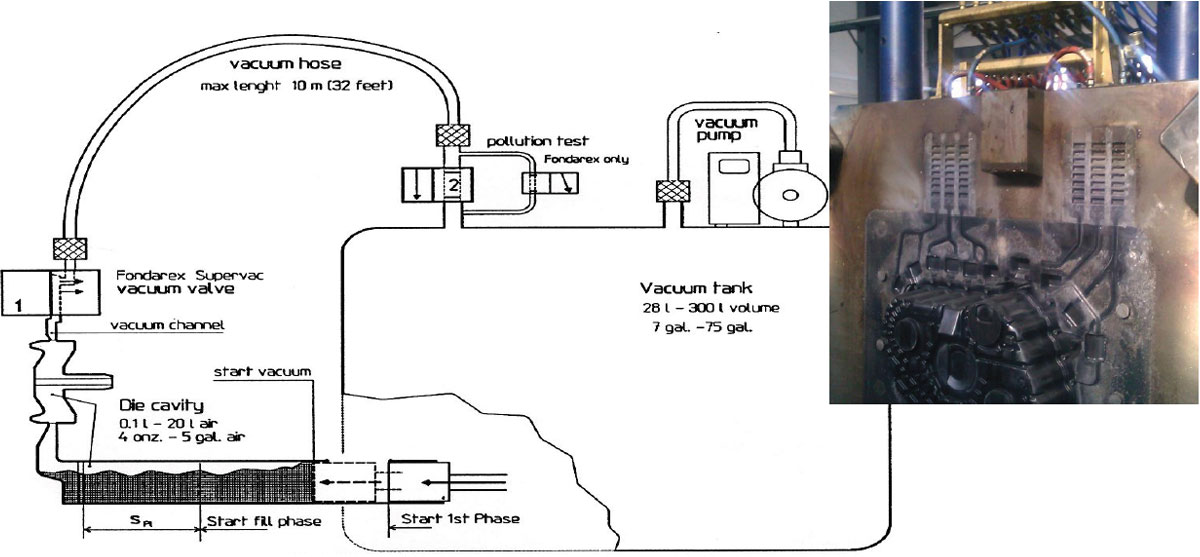

Vacuum die casting technology |

|

Proficiency in the use of vacuum die-casting technology, the mold to achieve vacuum die-casting and normal die-casting switching functions, the use of this technology in all die casting units of the company;

All molds are reserved for vacuum die casting.

No flash casting | |

| Claim:

Advantage: |

Concentrated melting furnace | Dumping furnace | Shot blasting machine |

|

|  |

| Serial number | Tonnage | Existing | New addition |

| 1 | 180 tons | 1 | |

| 2 | 300 tons | 1 | |

| 3 | 400 tons | 0 | 3 |

| 4 | 500 tons | 1 | |

| 5 | 650 tons | 1 | 2 |

| 6 | 800 tons | 1 | 2 |

| 7 | 1250 tons | 1 | 2 |

| 8 | 1650 tons | 0 | 1 |

| 9 | 2000 tons | 0 | 1 |

| 10 | 2500 tons | 0 | 1 |

| Total | 6 | 12 |

Note: There are 6 existing units, and the remaining 12 units will increase at any time according to market conditions.