Bolong inherits the superb mold design theory and manufacturing technology accumulated over the years and optimizes and innovates, introducing high-precision mold processing centers, CNC engraving and milling machines, mold clamping machines, wire cutting machines, EDM machines, high-precision grinding machines and other cutting-edge equipment. The company's mold products have higher technology content and longer service life.

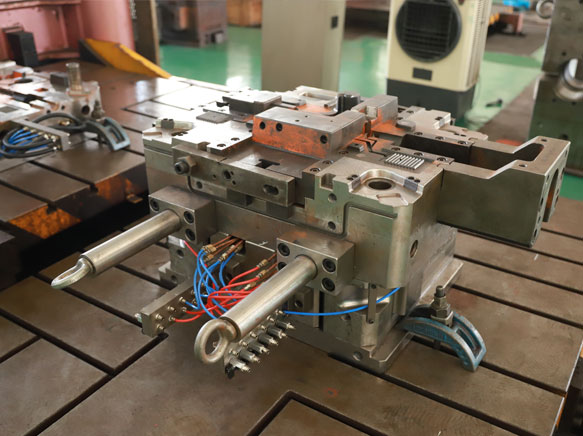

Mold workshop | Mould closing machine |

|  |

Mold temperature machine | |

|  |

Automatic temperature control, dual channel mold heater;

Mold cooling system | |

| 1、Cooling water pipes independent setup can contorl the valve,You can switch the valve at anytime.

|

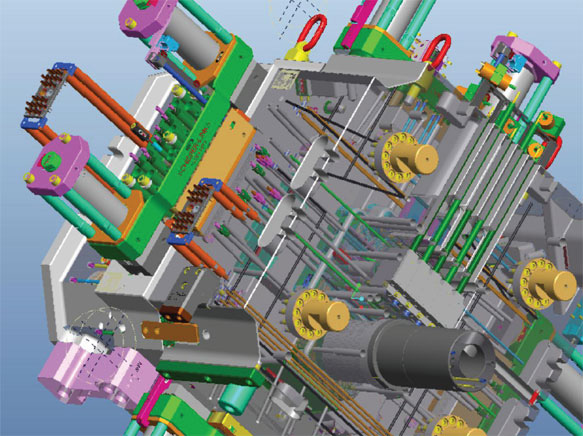

Die secondary squeeze technology | |

| |

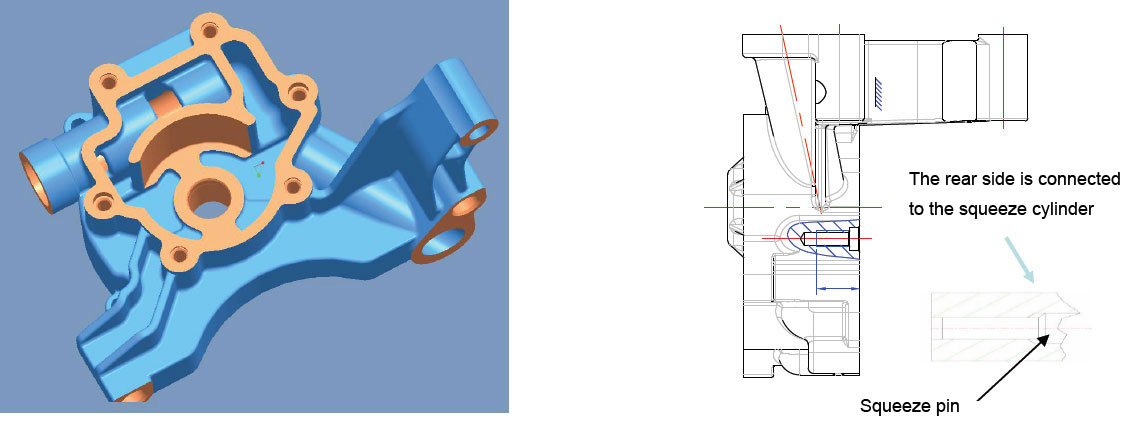

Through the analysis of the three-dimensional model, the part marked by the red arrow may have a large wall thickness due to the setting of the transition link and the process rounding, and the casting hot section is formed to shrink during the die casting process. In the process and mold design process

Consider the use of a partial extrusion device (extrusion principle: in the process of die casting, the extrusion device is started immediately after the end of the rapid injection, and the secondary extrusion is performed locally to increase the internal quality density of the product.)